Classification of “Pneumatic Actuator ”

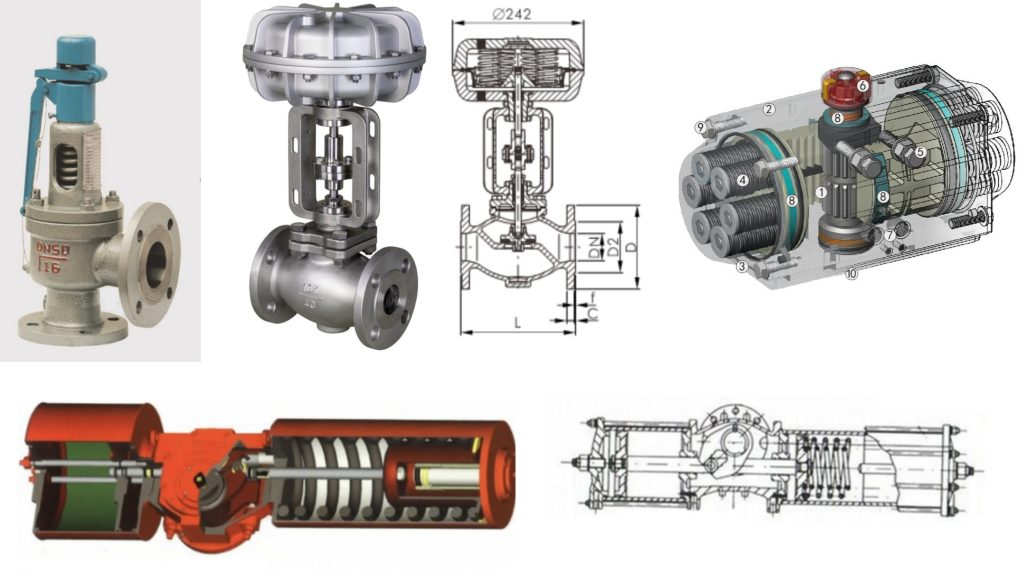

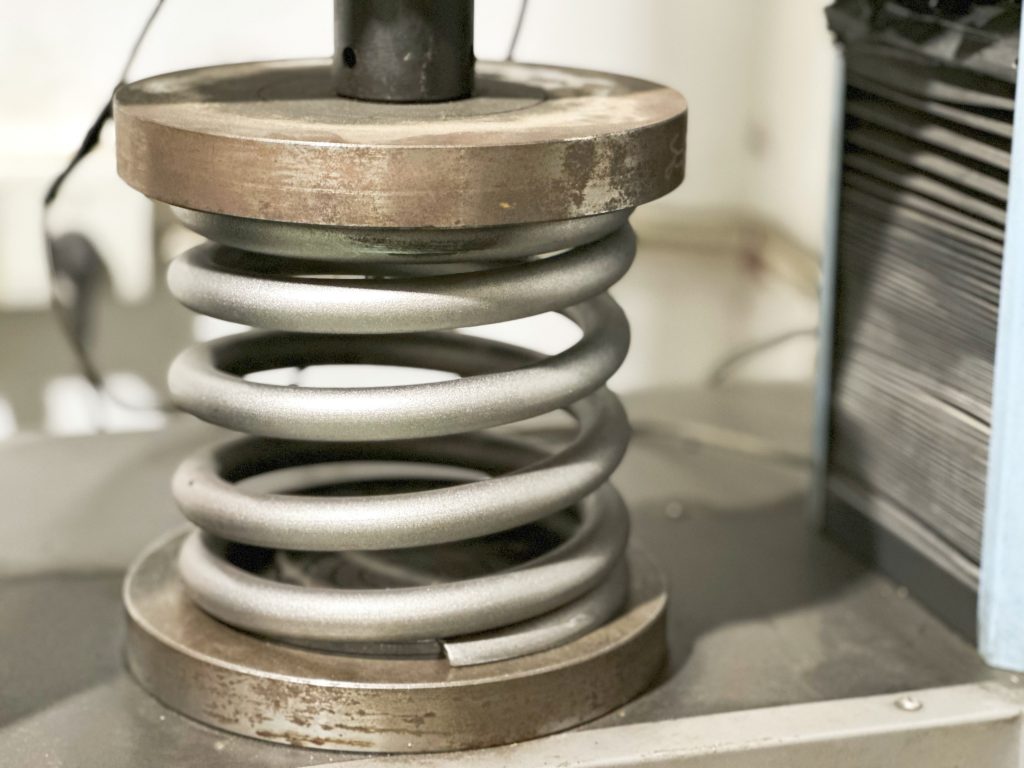

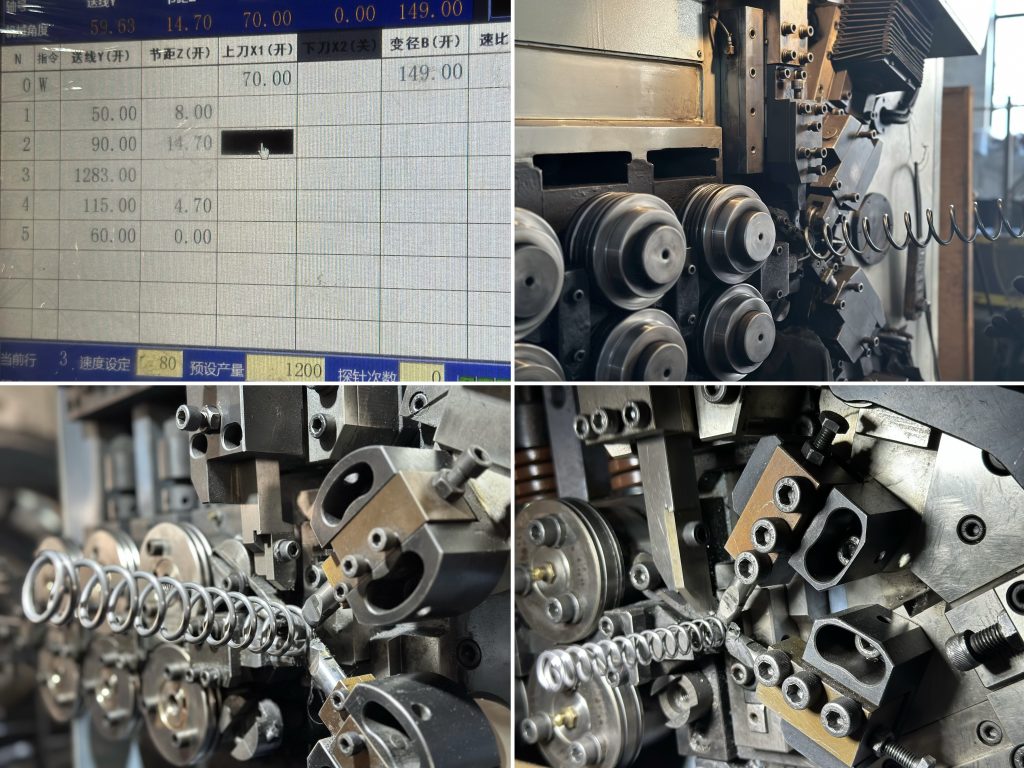

Spring Application in Pneumatic Actuator Mechanism Classification: Pneumatic actuator mechanisms can be classified based on structural forms and pneumatic state requirements. Classification by Structural Forms:Diaphragm Type/ Piston Type/ Scotch Yoke / Gear -Rack Type Diaphragm Type , also known as membrane-type, using for valve regulation. They require lower air supply pressure and exhibit good control performance. (Linear …